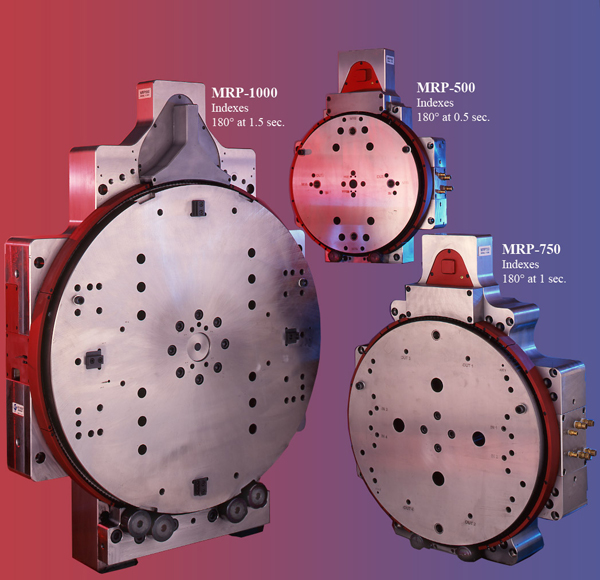

CTI Mold Rotating Plates are electric servo-motor driven for speed and indexing flexibility. All designs accommodate air circuits, water circuits and hydraulic knockouts. They are designed to fit into molding machines of up to 500-ton clamp tonnage.

When rotating a mold within a horizontal machine, the use of a CTI Mold Rotating Plate (MRP) for fast shot-to-shot sequencing has the following distinct advantages:

- Infinite adjustments can be made to the angles in which the mold indexes.

- Mold indexing is extremely fast for optimum material bonding.

- The MRP can be used on all electric molding machines in “clean room” molding.

- The mold coreside cooling is available through the MRP.

- In–machine serviceability with minimum machine downtime.