Multi-Shot molding allows parts to be made from multiple shots of either the same or different materials and/or colors.

It is used to eliminate assembly processes, or to create specific part characteristics.

Since building our first multi-shot mold in 1958, we have developed and manufactured many varieties of multi-shot mold configurations, including:

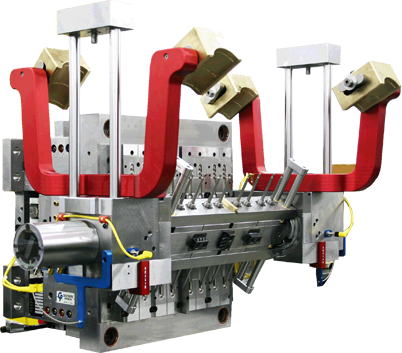

- LIT (Low Intertia Turning) – This CACO PACIFIC patented design innovation is a proven way to efficiently mold multi-shot parts, offering substantial savings in material.

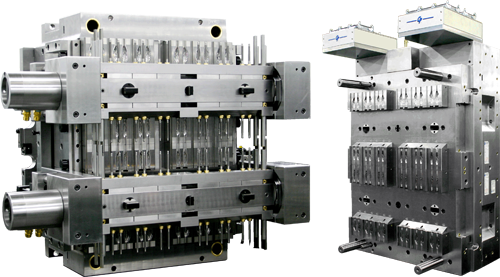

- MAPP (Multiple Alternating Product Positions) – This new technology for movement of parts that is especially useful in parts requiring more than two shots. Patent Pending.

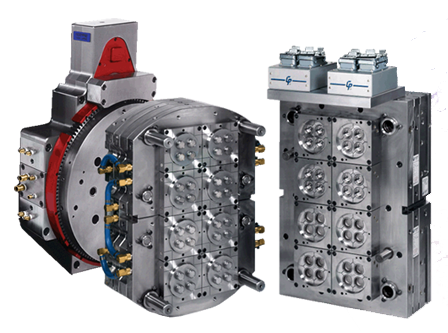

- Mold Rotation – Using our CTI branded Mold Rotating Plate (MRP).

- Robotic Part Transfer – Transferring parts within a single machine or multiple machines.

- Linear and Rotary Shuttle

- Internal Mold Rotation

- Core Back

Our expertise in optimizing part geometry helps assure a successful application.

We typically integrate complete multi-shot systems at our facility so that your project is delivered fully tested and production ready.