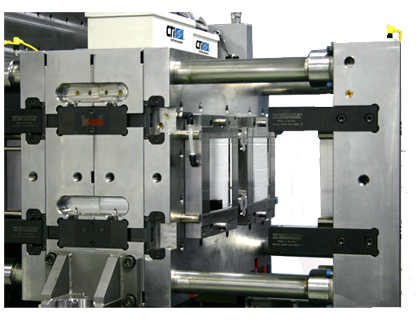

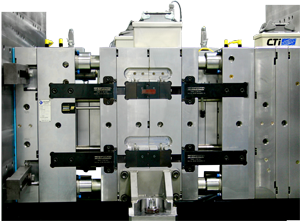

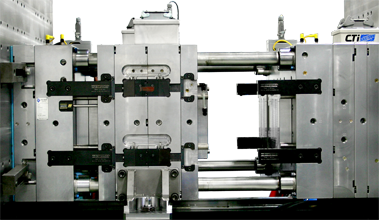

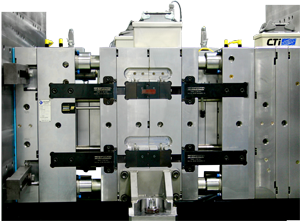

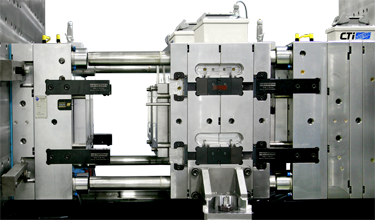

Tandem molds differ from stack molds by alternating the opening of the parting lines.

One parting line is held closed by a proprietary clamping system while the other parting line opens for part ejection. By alternating the parting line opening it may be possible to use a smaller injection unit to create the same output as an equivalent stack mold.

Another benefit of Tandem molds is that each parting line can have its own injection profile allowing for variations in critical part molding parameters or completely different parts within the same mold.

We have specific experience designing and building Tandem molds and associated hot runner systems.